New Application| SLS 3D Printing to develop Pet Ear Endoscope Probes

According to research from Harvard, auditory input accounts for 11% of the information we gather, making ears one of the crucial sensory organs. When inflammation or damage occurs in the ear canal or eardrum, it necessitates a visit to the hospital for an ear endoscopy.

So, when pets have ear conditions, do they also require ear endoscopy? What are the differences in the ear endoscopes used for them?

In fact, it's quite common to conduct regular ear-related check-ups for pets nowadays, especially for cats and dogs, which are prone to ear problems. Many pet hospitals have dedicated ear endoscopy equipment.

[Integrated pet otoscope (left) and handheld otoscope (right)]

Usually, the principles behind these devices are similar, but depending on the pet's breed and size, different sizes and shapes of earpiece probes are needed. While these devices often come with a set of probes, as the variety of pet breeds increases, the randomly provided probes can't meet all demands. Additionally, it's challenging to find probes produced and sold separately on the market. Addressing this gap in the market, a well-known domestic 3D printing digital medical solutions provider—Black Flame Medical, uses SLS technology to develop pet ear endoscope probe products.

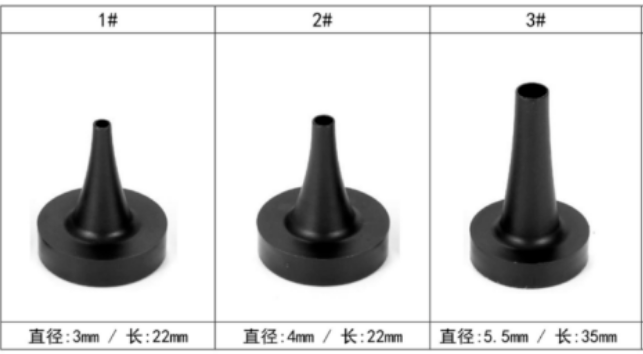

[Different size of probes made by tradition processing]

These products not only require high precision in shape and size but also need light-shielding properties to prevent light loss within the channel. Moreover, since the probe is relatively thin at the bayonet position and requires repeated installation and disassembly during replacement, the material also needs to have high mechanical strength and good wear resistance, which are difficult for FDM and SLA technologies to balance.

[The printed ear probe for testing]

Given these requirements, TPM3D engineers suggest using Precimid1172Pro GF30 BLK polymer powder printing. This is a gray-black 30% glass-reinforced nylon 12 material, characterized by high printing dimensional accuracy, good mechanical strength, wear resistance, high reuse rate, etc., which can meet the requirements of ear endoscope probes well.

[Partial probe printed using TPM3D PA12 powder]

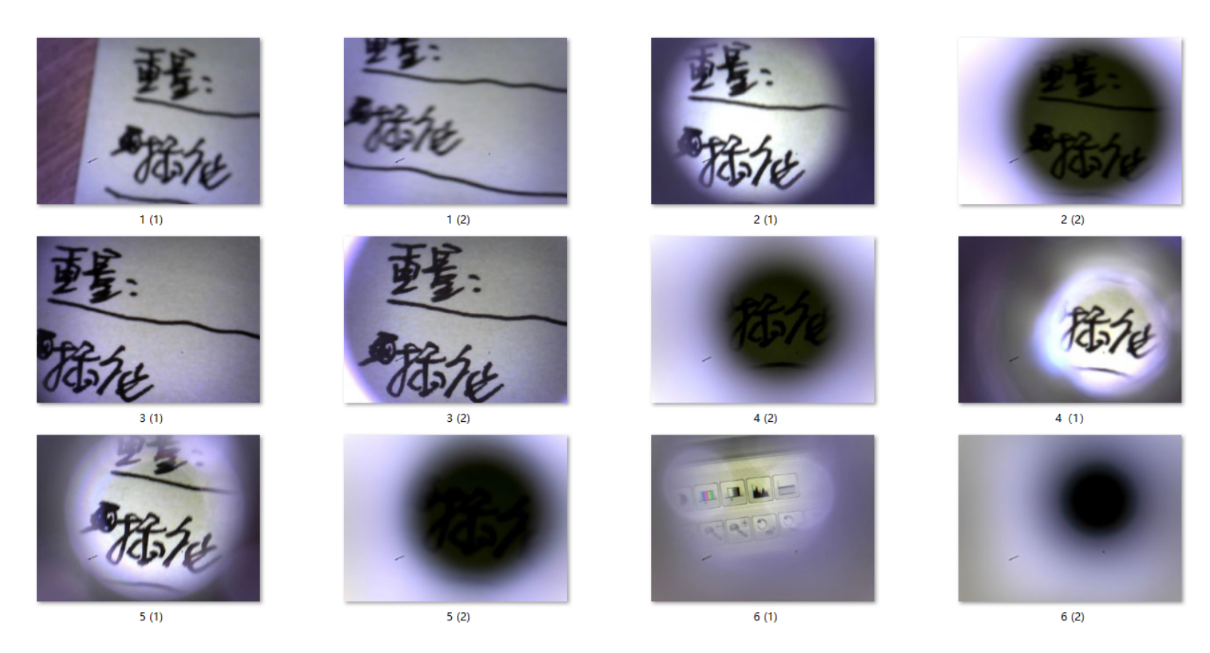

The printed probes have accurate characteristics, with dimensional accuracy within ±0.1mm, appropriate tightness when installed on a handheld electronic otoscope, and good bayonet strength, meeting the requirements of repeated installation and disassembly. Subsequently, Black Flame Medical designers conducted on-site tests of the probes, with the results as follows:

[Test results of several sets of SLS printed probes]

[The electronic otoscope installing sls 3d printed probe]

The designer is very satisfied with the preliminary test results and will continue to make rapid modifications and iterations to the product. Once the product is finalized, it will be directly mass-produced using SLS 3D printing technology. It is believed that we will see these products on the market in the coming future, that can help more pets recover.